NEW, under construction: worldwide-innovations-for-free com TEST IT:

Contribution against the energy and gas crisis!

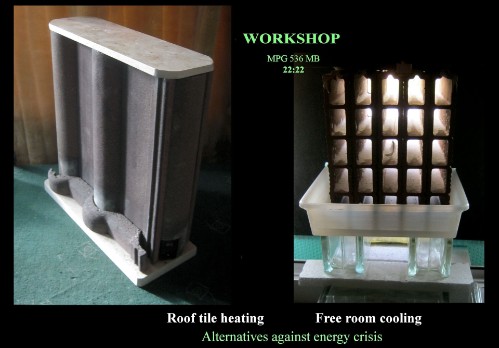

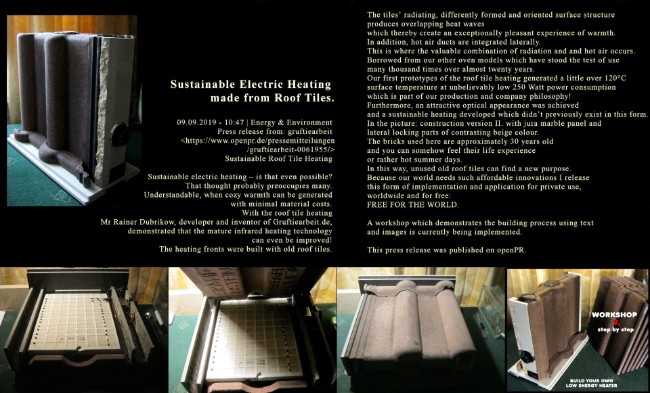

Highly economic power heating from roof tiles and free room cooling!

So, what do you do when gas or heating oil is rationed or becomes immensely more expensive?

When heating manufacturers are working to capacity and therefore cannot deliver more than before? When components are no longer in stock? When craftsmen are no longer able to come?

When tens of millions are looking for immediate heating alternatives? Where shall these come from?

Originator Rainer Dubrikow: Well, let's build our space heating from available and cheapest resources! I bet we can build an immensely effective, extremely economical heater, which also looks great and keeps a room cozy and warm in the winter. Power consumption is just 250 watts!

For this, 3 - 4 old tiles/roof tiles or tiles per oven, odds and ends, as well as high-temperature silicone and some quartz sand our free building instructions are all you need.

This means that instead of a conventional small fan heater with approx. 1500 W, 6 roof tile furnaces can be operated with the same power consumption. This heats an entire apartment, which a fan heater can never do!

Conclusion I.: Tremendous electricity savings II. You can do this yourself. III. Simply with the tiles of an old barn, you can build heaters like this, for a small town or a bigger village: instantly and extremely cheaply. Resource-saving and long-lasting.

You can do this a million times and immediately in all countries with the same problems!

Manufacturers of this world are not able to implement this immediately, but WE, the users!

The same is feasible for free room cooling (3rd contribution in the workshop: worldwide-innovations-for-free.com). Just with the thereby saved energy, one can operate e.g., several roof tile heaters, for a whole winter. This saves immensely and makes us more independent!

This is how our future must and will be: as SELF-SUFFICIENT and energy-saving as possible!

This free workshop will enable you to implement this and thus help people who are currently suffering particularly from the energy crisis.

WORKSHOP. English = Link:

https://drive.google.com/file/d/1zY2GS3wXXfoHjymCreinUqunvRC-i3Um/view?usp=sharing

Workshop 001 - 003 in German: worldwide-innovations-for-free

https://drive.google.com/file/d/1DgHIlkca-XnnUz0FLp3LAcHMMlAytvtl/view?usp=sharing

The WORKSHOP IS FREE. You will not have to pay for learning! FREE LEARNING.

Workshop I.: BUILD YOUR OWN LOW ENERGY HEATER.mp4 PART I.

Download

FREE for Commercial use! "Motionversion" = stop and go; stop and go...

Our workshops are free of charge. Innovations as well. NEW: Popcorn as packing material FREE WORLDWIDE!

We are happy about donations. Please via Paypal account: zentraleBRD@aol.com

Workshop V.: BUILD YOUR OWN LOW ENERGY HEATER MADE FROM ROOF TILES (2021.12) NEW: PART II.

WORKSHOP V.: build your low energy heater made from ROOF TILES + avi.avi

Download

Also: MOVIE - "DANCE/Tanzfilm" including Workshop I. = Heater MX & SL (Bonus:+ Heater without Thermostat) + Workshop V.

CRYSTALHEATER TECHNOLOGY:

Knowledge about the behaviour of crystals in a furnace construction

Based on more than 2 years of practical application and the frequent cutting/processing (mainly of amethyst crystal plates) we have the following experience:

1. It has been proven that crystals have storage capacities. But why would Mother Nature develop empty storage?

2. When customising the very first crystal oven 001 (the mother of all crystal ovens), I could literally "hear/feel" how it got into contact with me. "Why are you destroying me?" It's true! It also "defended" itself because I cut myself on its sharp edges 7-8 times. Nevertheless, the model was completed. In terms of dimensions, it was assembled simply by a feeling. When it was switched on for the first time, I could feel the contact but this time, it was pleasant: "oooh ahhr“ Initially, I got goose bumps which still appear every time I tell this story.

3. As the designer, you always strive to find further improvements. But this was not possible in this case, regardless of whether the oven was built thicker or thinner. Even the thickness of the wall of the amethyst druse(s) was ideal. If the prototype is NOT improvable, that should be something "to think about". Furthermore, ever since then, I have NEVER been cut again. That can't be a coincidence, as people who work with similar materials with sharp edges cut themselves every now and then.

4. Therefore, I claim that crystals have a friendly/communal knowledge. This means that the knowledge or the experience is transferred to others, similar to the behaviour of school of fish. Here, they all "know" what one of them will set off ***

5. Furthermore, I have also come across "alpha crystals" ***. You can sense/feel this when heating them up, or more specifically, when they are heated. With normal room temperatures, they are all passive mainly because they were born under pressure and heat and this represents their natural living environment.

6. Using them as a heater or built into the oven, we lead them back or give them the necessary temperature kick to become more active. What is really important is heating and cooling slowly so that the structures of the collection of single crystals which have merged in the form of a druse or a plate are not destroyed (see picture 1). For this reason, single long solitaire crystals such as quartz (rock crystal) are not suitable due to their measurements as each of the crystals suffer due to the changes in temperature (hot feet, cold head) and are under stress. How is healthy radiation supposed to be achieved?

7. The infrared radiation generated by them is not achievable with structured glass surfaces. The difference is also evident when you look at the structure in the intersection: sustained from the agate shell, smaller pieces grow/push their way out. Thereon, large pieces, some can be additionally "heated up/flamed" by the smaller pieces (picture 1). Thus the comparison suggests itself: multiplication by division! We increase the radiation by the number of pushed out crystals which are superimposed and interacting. As well as later the amount of radiation surface (here, 5 per crystal). This results in (because of the irregularity in the construction) multiple emitting and intersecting heat waves (here I call these "turbulent heat radiation") which does not directly "focus" on one , but rather is "more or less ambient", room-filling, softer and milder = healthier!

In the future of heat technology, we will not come by heated crystals anymore. Also because the sight is already sublime. We generate radiation temperatures of around 120°C. For amethysts, this is only warm and cosy. The temperature doesn't change its colour either! Only at 500°C will the amethyst change to a yellowish colour and become citrine! What was also striking was that some crystals were "clearer". Self-cleaning. Also the fact that a significantly thicker size of crystal/wall of the crystal becomes hotter than a comparably smooth stone (which also has a much smaller surface area and therefore should be a lot hotter). Also a crystal formation has almost no heat/transmission losses! Conclusion: crystals have one task and it is to be found their nature i.e. HEAT ***

Findings by Rainer Dubrikow. Germany, 11.11.11

Developer of crystal heating technology: https://patents.google.com/patent/DE102009011282A1/en

FREE License WORLDWIDE!!!

Addendum: suitable tiles for the application as shown in the patent office drawing (most effective, as this creates the largest area). Are also easy to recognize for the layman, since the back of the tile looks sand-colored to reddish.

https://patents.google.com/patent/DE202015005332U1/en?q=stromlose+k%C3%BChlrippentechnologie&oq=stromlose+k%C3%BChlrippentechnologie

https://pressnetwork.de/kostenlose-raumkuehlung-room-cooling-free-of-charge/

Furthermore, these are very light tiles compared to solid granite or porcelain stoneware. With these, you don’t need any paper inserts, as mentioned in the DPMA publication, because they draw moisture up very well. In the picture above: small conversion. Ideal: narrow but across the width of the window and at the suction height of the tile material. Everything standing in a water tub!

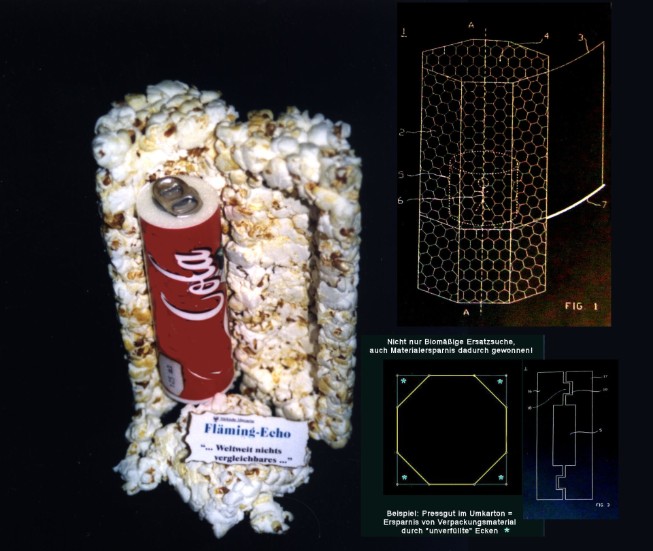

Popcorn as packaging material: Edible packaging is finally possible! FREE License WORLDWIDE!!!

The world is in desperate search to supplementing Styrofoam packaging.

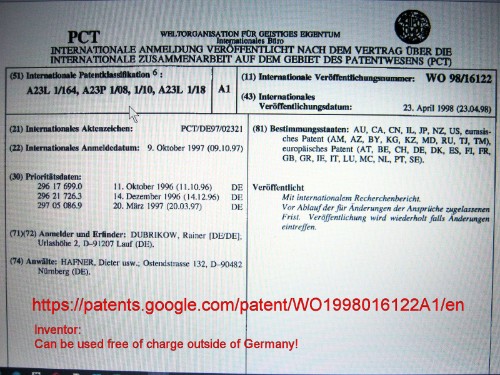

Mr. Rainer Dubrikow already registered a WORLD PATENT in 1998: pressed popcorn as packaging material: in sweet, salty or neutral flavour with or without a tear-off sleeve.

The however greatest benefit of the product is clearly that it is safe and tasty for consumption.

This revolutionary innovation is released worldwide free on the website www.gruftiearbeit.com under FREE LICENSES (= page 10) (except for Germany) under the condition of stating the author’s credentials (copyright).

https://patents.google.com/patent/WO1998016122A1/en

The process in short summary: Corn is popped up in hot air, gathered into shape and pressed immediately while still hot.

A single pressing- process results in a permanent molding. Popcorn compressed with this method possesses an equal solidity to Styrofoam.

Usage of this method may increase the brand-awareness in terms of environmental-friendly packaging, regardless of whether it is packaged with canned cola, bottle of wine or any other figure shape.

This innovation is twice as intriguing since it is absolutely sustainable for natural corn can be grown regionally around the world.

Today there is loose popcorn as packaging material. In our case, however, it is pressed popcorn, the evidently more solid version. A rod, a half, a section or a cross section can be pressed.

Another packaging advantage compared to loose materials: the respective item can be securely fixed or wedged even when the box is not completely filled = additional packaging savings!

The goods to be shipped are securely packed in the box. Another immense advantage is that it avoids heavier packaged goods to slide back and forth or "always rock" freely when loosely packed.

In conclusion: both versions have a justly futuristic potential in comparison to Styrofoam which is also available loose and pressed! !

Since our world needs such innovations IMMEDIATELY, this is being released WORLDWIDE for the fastest distribution: no license fees incurred! Since the creation requires work effort and investment, your financial support is welcome.

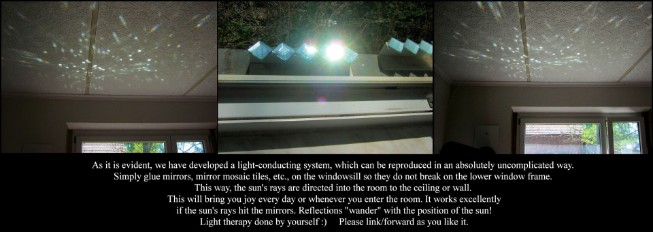

BONUS = Innovation: catch sunrays